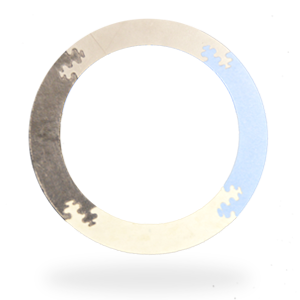

100% expanded PTFE gasket with a fully encapsulated corrugated, stainless steel insert. The patented construction allows the gasket to maintain high tightness throughout thermal cycling in all chemical services.

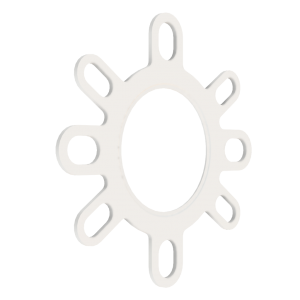

Semi-metallic ePTFE gasket. Patented construction of the spring-energized metal insert allows the CycleTight® gasket to fit securely into the manway cover and provide multiple reuses across a broad range of chemical services.

Building upon proven CycleTight® technology, the engineered V-Notch™ allows the gasket to be both self-centering and reusable in ISO tank manway lids.

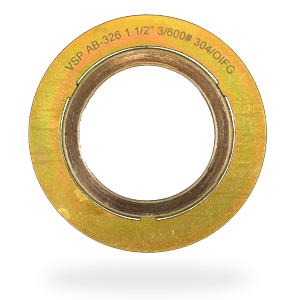

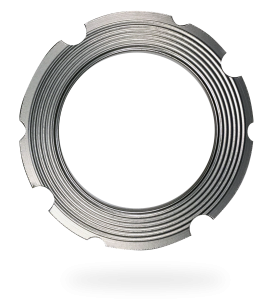

A revolutionary low-stress anti-buckling spiral wound gasket designed for all flange pressure classes and flange types, even class 150 lap joint and slip-on flanges!

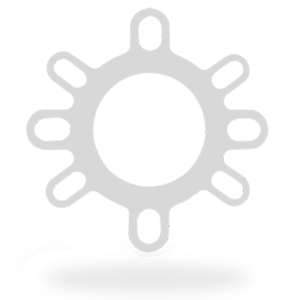

Reduced area gasket design technology ideal for fragile or low bolt load flanges. Patented gasket design technology creates a modified full-face gasket with reduced gasket contact area to match available flange bolt load and gasket material compression and stress requirements.

Expanded PTFE reinforced with an aggressive 316 stainless steel tang core which dramatically increases the mechanical integrity and virtually eliminates gasket creep, increasing the blow-out resistance and making the gasket suitable for extreme temperatures and pressures.

Combining PITA® and OPRA™ technologies creates an extremely low stress to seal, high-tightness gasket for FRP piping and equipment flanges.

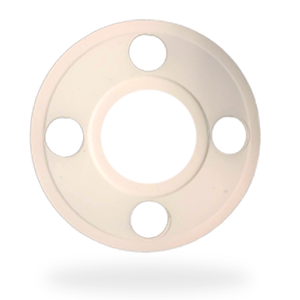

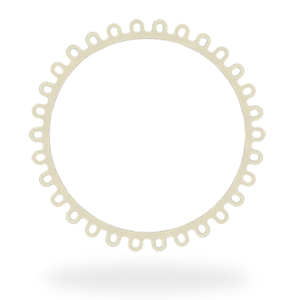

The lowest stress to seal, 100% PTFE based gasket. Designed for chemical services on FRP / plastic and thin, flat-faced flanges such as API 650 manways.

A fire-safe PTFE spiral wound gasket that provides low stress to seal, high tightness and PTFE inertness and purity.

Unique segmented-gasket technology providing tighter, more mechanically secure fits between gasket segments that obsoletes all other jointing/dovetail methods. Virtually invisible joint after compression.

The TorqKit™ packages and protects all customer-specified flange assembly/reassembly components in one box/package, including assembly instructions, torque guides, and QC documentation tag.

A drastic improvement to the age-old PTFE envelope gasket. One-piece, unitized construction of the PTFE envelope and chemically inert filler completely encapsulates the corrugated insert, completely eliminating installation issues caused by the loose envelope.

A gasket designed specifically for API 650 manways to seal with low bolt load on weak manway flanges.

Initially designed for thin, under-bolted stainless steel flanges on tank containers, this gasket material/design excels in all flat face, class 150 and PN 10 Din flanges in chemical services.

ENCASE gasket exceeds industry standards and delivers high tightness sealing with extremely low creep.

Part of VSP’s next generation of gasket technologies for bulk transportation equipment and fixed-based plant operations.

A unique solution that combines the durability of PTFE with the flexibility of rubber without sacrificing sealing performance.

Under bolted flanges in harsh chemical environments demand uncompromised purity and performance. Non-Metallic PITA™ utilizes a non-metallic core, completely encapsulated in expanded PTFE (ePTFE) facings, to provide exceptional resistance across a broad range of chemicals.