RideTight is a turnkey compliance program is a one-stop-shop for all tank car seals, exclusively from VSP Technologies

- Education and Best Practices Training to ensure Compliance

- Robust QA documentation and Assembly/Installation guidance

- Seal Selection and Updated, Detailed Specifications

- Expert, timely Root Cause Failure Analysis and corrective action support

RideTight, the proven Six Sigma Fluid Sealing Management Program synonymous with Sealing Reliability and Compliance, will now include Service Equipment Rebuild Kits in an expansion of RideTight, VSP Technologies’ regulatory compliance program.

The RideTight Program – All-in-one package, under one roof, from the company you’ve trusted for years

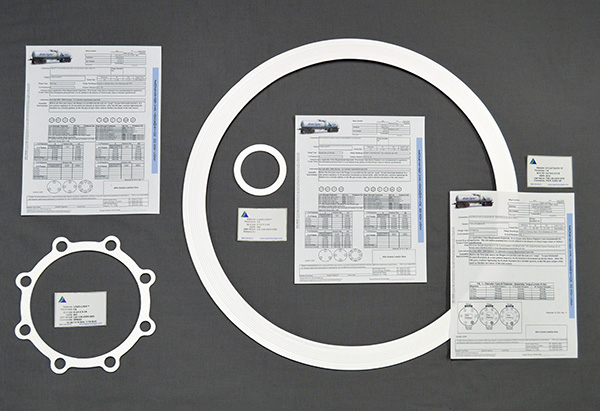

Gaskets and Assembly Sheets

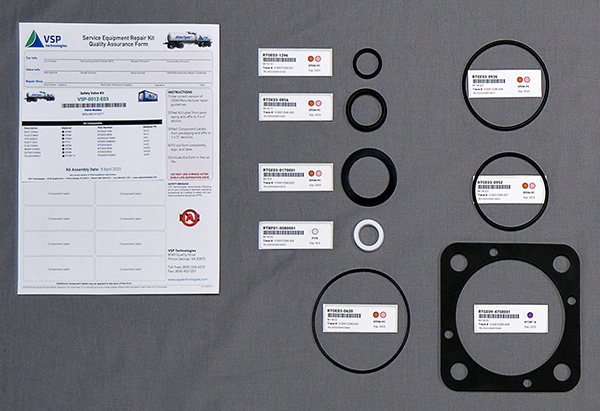

SERK – Service Equipment Rebuild Kits

RideTight QA Packaging

- Documentation for Compliance Requirements

- Material per Specification

- Parts clearly labeled with cross-check label

- Quality Assurance/Tracking Form

- Detailed Assembly/Torque Sheet

- Shelf Life Expiration Date

Training

Function Specific Training conducted at repair shops, loading facilities, and customer sites. This training is provided at no cost to the shipper/client and has proven to be extremely valuable for the industry since the RideTight Program inception in 2004. Topics include: materials, bolted flange assembly specifics, Service Equipment (SE), best practices, and lessons learned from root cause failure analysis.

New Equipment

VSP Technologies invested in new technology and equipment expanding the RideTight program to include Service Equipment Rebuild Kits . This investment ensures we can continue to provide world class service to our customers for all tank car seals.

FTIR Material Spectrometer

Due to the critical nature of the commodities(assets) transported by tank cars, material verification, for elastomers in particular, is a valuable Quality Assurance Compliance Check . Using FTIR ensures material specification compliance, and improves sealing reliability.

Optical Comparator

Verification of the Service Equipment (SE) seal dimensions is another Quality Assurance Compliance Check to ensure the supply chain is compliant.

Dimensional verification also aids in Root Cause Failure Analysis (RCFA) promoting shipper operational efficiencies and at the service provider level.

Durometer Gauge for Elastomers

Another critical aspect of the Service Equipment (SE) components is the specific hardness, or durometer of the elastomers. This Quality Assurance Compliance Check confirms the elastomer seal is within the specified durometer range for optimum sealing reliability. Through this in-process check, VSP can ensure these parts are supplied correctly.

Durometer verification also aids in Root Cause Failure Analysis (RCFA) promoting shipper operational efficiencies and at the service provider level.

Automated Packaging

VSP strives to bring value in each step of the Service Equipment Rebuild Process.

Each component is individually packaged with an identification and tracking label. During Service Equipment (SE) repair the Technician performs the final Quality Assurance Compliance Check when checking the component label before installation.

This automated equipment is an example of continuous improvement in compliance with VSPs’ ISO-9001:2015 program.

Packaging Tables with Heat Sealers

Each SERK component is packaged individually. After a Quality Assurance Compliance Check to ensure all components match they are then placed into a heavy-duty 4 mil poly package before being hermetically sealed. This process eliminates concerns of cross-contamination with similarly appearing items.

Take the next step in reducing NARs and streamline your Tank Car sealing

Your RideTight program sealing materials and sizes per your approved specifications.

Improve shop efficiency by ordering all Gaskets and Service Equipment Rebuild Kits from VSP Technologies. We will ship everything in one bag labeled by tank car number.