Ecomap™

VSP's Environmental Compliance and Maintenance Program is designed to incorporate environmentally sound practices, eliminate fugitive emissions, and aid a company's sustainability performance.

RideTight®

Designed specifically for railcars, tank containers, and tank trucks to manage their fluid sealing materials, selection, sourcing, and installation processes to ensure reliability and integrity.

RideTight® Hydro2Hydro®

Designed with reliability necessary for tank containers in mind. The VSP Hydro2Hydro® program is a part of the RideTight Program® and is focused on reducing your Total Cost of Ownership (TCO) by making gaskets that last 5 years or as long as the time between required hydrostatic testing.

SiteTight™

SiteTight™ Engineered Fluid Sealing Solutions for Industrial Process Facilities SiteTight is a Six-Sigma approach to Fluid Sealing Management that enhances the safety and reliability of fluid sealing applications by identifying …Hose Program

Hose Program Engineered Fluid Sealing Solutions for the safe transfer of goodsVSP’s Hose Program is a Six Sigma approach to Hose Assembly and Coupling Management that enhances the safety and …VSP Technology Approach

Our Fluid-Sealing Management Programs are based on proven Six Sigma Methodology for best practices in the fluid-sealing process.VSP Fluid Sealing Management Program Six Sigma Methodology/Approach

- Identify and understand limitations within current processes

- Optimize processes by designing and implementing solutions based on particular needs

- Control future outcomes by establishing standards and conducting training to ensure solutions – and cost savings – are sustained

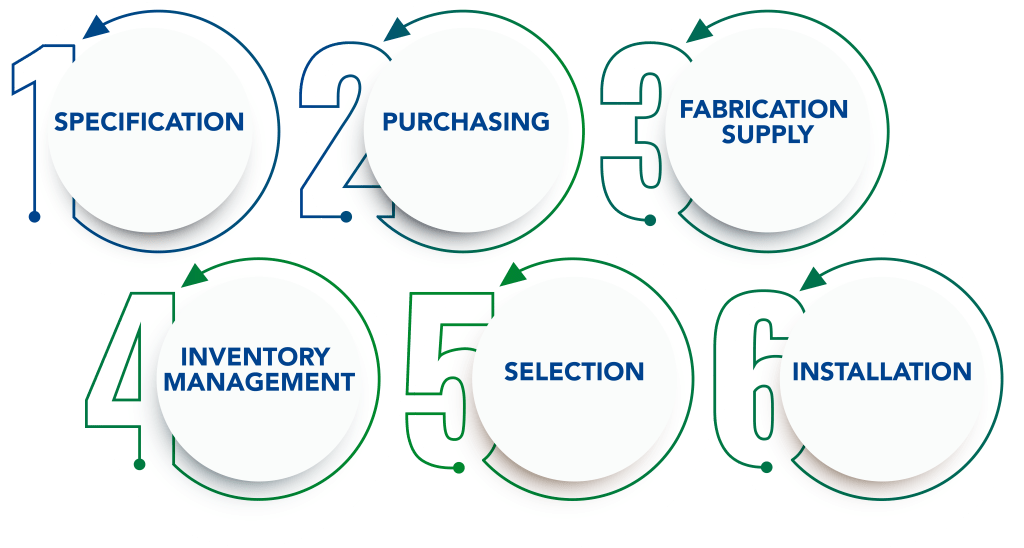

The Fluid Sealing Process

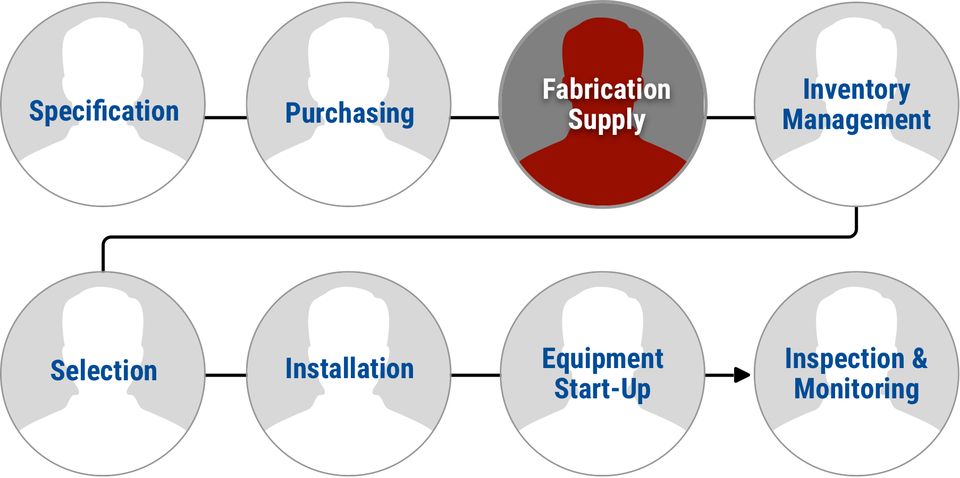

The Traditional Competitor’s Approach – Who is Managing This for Your Site?

Most distributors only impact one small part of the gasket-use process, but at VSP Technologies we’re involved from start to finish. We help customers manage parts of the process that are currently not addressed, improving efficiency and saving time and money.